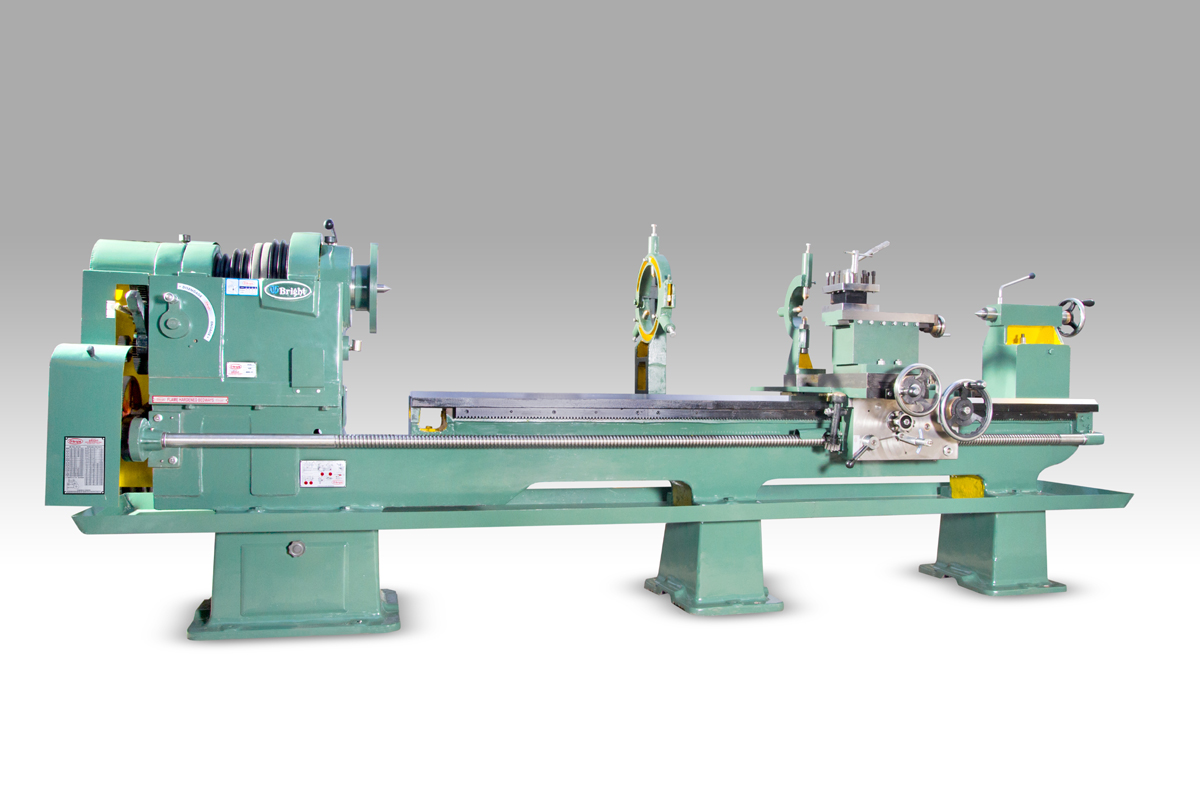

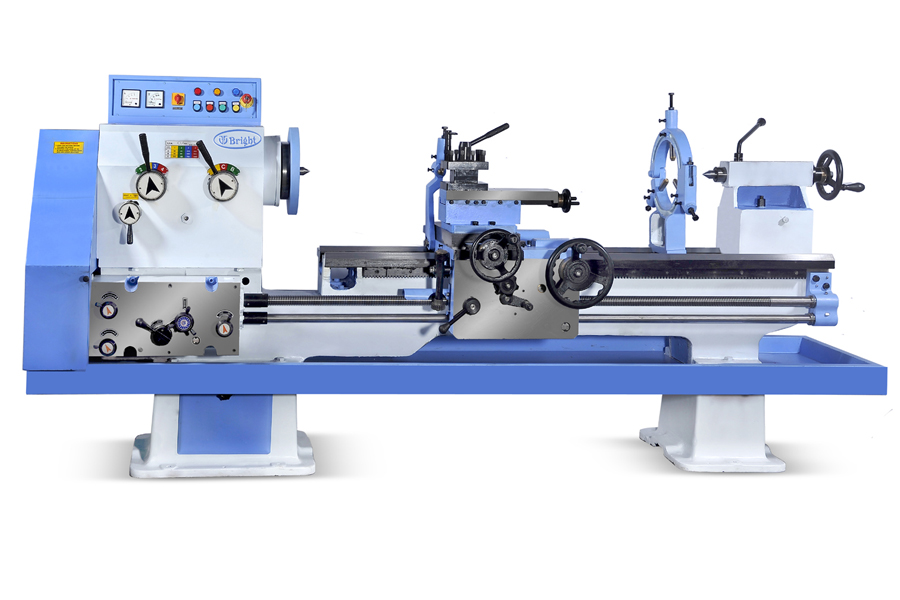

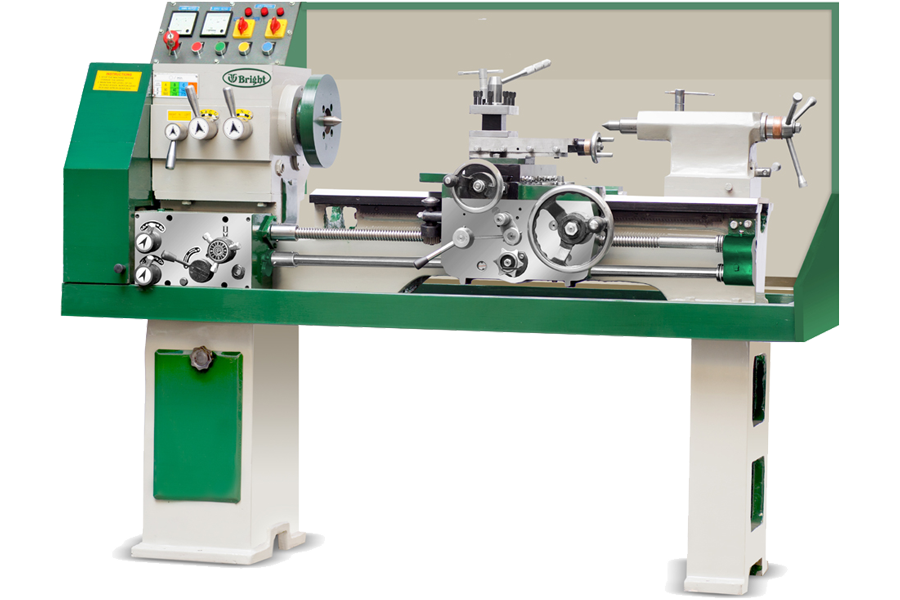

Extra Heavy Duty Cone Pulley Lathe Machine Series-380

Quick ContactBright Engineering Works offered sweeping range of lathe machines one of them is EXTRA HEAVY DUTY CONE PULLEY LATHE MACHINE.

Extra Heavy Duty Lathe Machine is most required lathe machine in field like Heavy engineering industries, Marine parts manufacturing industries etc.

Keeping all factors in mind We the Bright Engineering Works has made specially designed very heavy and sturdy machine to withstand against heavy load.

It has many variant according to various sizes of jobs.This kind of lathe machine mainly used for machining of long jobs.

Bed:-The bed is made of high graded casting and its heat treated with high quality induction hardened and grounded to opt long lasting life, after it well machined.the design of bed very sturdy to resist any kind of vibration.

Head Stock:-The head stock is made of good quality graded cast iron material and it is well machined,The spindle is made good alloy steel and its fully heat treated and grounded,it runs on best quality bearings, and bushes where and when it requires.

Carriage: The carriage is located between the headstock and tailstock and serves the purpose of supporting, guiding and feeding the tool against the job during operation.

Tail Stock:- the tailstock is made of good quality graded cast iron material and it is well machined,maintained its alignment with head stock to getting best accuracy.tailstock spindle is made good alloy steel ,fully heat treated and grounded,

Legs: The legs carry the entire load of machine and are firmly secured to floor by foundation bolts.

Special Features

- Good quality graded casting with high quality hardened and grounded bed ways to resist wear and tear and get extra longer life.

Main spindle and Tail stoke spindle will be hardened and grounded.

Pulleys and gears are to be Dynamically balanced.

Fully oil bath Appron gear box.

Steel parts are made of Alloy Steel.

Bushes are made of Gun Metal Material.

Standard Accessories

- Flame hardened and grounded bed ways.

Chuck back plate

Center Adapter

Live and Dead center

Tool Post Spanner

Motor Pulley

Set of gears for British and Metric thread

Safety Guards

Extra Accessories

- Face plate

Carrier plate

Steady rest, Follow rest

Taper Turning Attachment

Motorised coolant pump and its tank

Rear Tool Post

Norton gear box (Quick change gear box)

Electrification

Specification

| Model | BL-1/XHD-380 | BL-2/XHD-380 | BL-3/XHD-380 | BL-4/XHD-380 | BL-5/XHD-380 | BL-6/XHD-380 | BL-7/XHD-380 |

|---|---|---|---|---|---|---|---|

| Admit bet. Center in mm | 910 (35¾ inch) | 1520 (59¾ inch) | 1825(71¾ inch) | 2435(95¾ inch) | 3045(119¾ inch) | 3655(143¾ inch) | 4265 9168 INCH) |

| Length of Bed in mm | 2135(7 Ft) | 2745 (9 Ft) | 3050 (10 Ft) | 3660(12 Ft) | 4270(14 Ft) | 4880(16 Ft) | 5190(18 Ft) |

| Width of bed in mm | 380 (15" inch) | 380 (15" inch) | 380 (15" inch) | 380 (15" inch) | 380 (15" inch) | 380 (15" inch) | 380 (15" inch) |

| Height of Centre in mm | 380 (15" inch) | 380 (15" inch) | 380 (15" inch) | 380 (15" inch) | 380 (15" inch) | 380 (15" inch) | 380 (15" inch) |

| Swing over bed in mm | 760 (29¾ inch) | 760 (29¾ inch) | 760 (29¾ inch) | 760 (29¾ inch) | 760 (29¾ inch) | 760 (29¾ inch) | 760 (29¾ inch) |

| Swing over cross slide in mm | 545 (21½" inch) | 545 (21½" inch) | 545 (21½" inch) | 545 (21½" inch) | 545 (21½" inch) | 545 (21½" inch) | 545 (21½" inch) |

| Swing in gap in mm | 1015 (39¾ inch) | 1015 (39¾ inch) | 1015 (39¾ inch) | 1015 (39¾ inch) | 1015 (39¾ inch) | 1015 (39¾ inch) | 1015 (39¾ inch) |

| Length of gap IFO face plate in mm | 190 (7½" inch) | 190 (7½" inch) | 190 (7½" inch) | 190 (7½" inch) | 190 (7½" inch) | 190 (7½" inch) | 190 (7½" inch) |

| MAIN SPINDLE | |||||||

| Type & Size of Spindle Nose | Threaded | Threaded | Threaded | Threaded | Threaded | Threaded | Threaded |

| Spindle Bore in mm | Standard-80mm,Optional-102,/125,/150 | Standard-80mm,Optional-102,/125,/150 | Standard-80mm,Optional-102,/125,/150 | Standard-80mm,Optional-102,/125,/150 | Standard-80mm,Optional-102,/125,/150 | Standard-80mm,Optional-102,/125,/150 | Standard-80mm,Optional-102,/125,/150 |

| No of Speed/Range in RPM | 8/37 to 392 | 8/37 to 392 | 8/37 to 392 | 8/37 to 392 | 8/37 to 392 | 8/37 to 392 | 8/37 to 392 |

| Morse Taper | MT-5 | MT-5 | MT-5 | ||||

| TAIL STOCK | |||||||

| Diameter of Spindle (RAM) | 57 (2¼" inch) | 57 (2¼" inch) | 57 (2¼" inch) | 57 (2¼" inch) | 57 (2¼" inch) | 57 (2¼" inch) | 57 (2¼" inch) |

| Travelling of Spindle (RAM) | 180 (7" inch) | 180 (7" inch) | 180 (7" inch) | 180 (7" inch) | 180 (7" inch) | 180 (7" inch) | 180 (7" inch) |

| Morse Taper of Spindle (RAM) | MT-6 | MT-6 | MT-6 | MT-6 | MT-6 | MT-6 | MT-6 |

| LEAD SCREW | |||||||

| Diameter of Lead Screw / TPI | 44.45 (1¾" inch) /4 TPI | 44.45 (1¾" inch) /4 TPI | 44.45 (1¾" inch) /4 TPI | 44.45 (1¾" inch) /4 TPI | 44.45 (1¾" inch) /4 TPI | 44.45 (1¾" inch) /4 TPI | 44.45 (1¾" inch) /4 TPI |

| THREADS | |||||||

| No of Threads / Range in mm without Norton Gear Box | 15/1 mm to 6 mm pitch | 15/1 mm to 6 mm pitch | 15/1 mm to 6 mm pitch | 15/1 mm to 6 mm pitch | 15/1 mm to 6 mm pitch | 15/1 mm to 6 mm pitch | 15/1 mm to 6 mm pitch |

| No of Threads / Range in inch without Norton Gear Box | 20/2 to 24 TPI | 20/2 to 24 TPI | 20/2 to 24 TPI | 20/2 to 24 TPI | 20/2 to 24 TPI | 20/2 to 24 TPI | 20/2 to 24 TPI |

| No of Threads / Range in mm with Norton Gear Box | 24/0.5 to 15 pitch | 20/0.5 to 15 pitch | 20/0.5 to 15 pitch | 20/0.5 to 15 pitch | 20/0.5 to 15 pitch | 20/0.5 to 15 pitch | 20/0.5 to 15 pitch |

| No of Threads / Range in inch with Norton Gear Box | 44/2 to 60 tpi | 40/2 to 60 tpi | 40/2 to 60 tpi | 40/2 to 60 tpi | 40/2 to 60 tpi | 40/2 to 60 tpi | 40/2 to 60 tpi |

| Floor Space Occupied in mm | 2660 X 1550 | 2970 X 1550 | 3275 X 1550 | 3585 X 1550 | 3895 X 1550 | 4205 X 1550 | 4515 X 1550 |

| Approx. Weight in Kgs | 1550 (1.55 M.T.) | 1700 (1.7 M.T.) | 1900 (1.9 M.T.) | 2100 (2.1 M.T.) | 2350 (2.35 M.T.) | 2550 (2.55 M.T.) | 2800 (2.88 M.T.) |

| Approx. Case Dimensions in mm | 2850 X 1300 X 1675 | 4150 X 1300 X 1675 | 4450 X 1300 X 1675 | 5050 X 1300 X 1675 | 5700 X 1300 X 1675 | 6300 X 1300 X 1675 | 6900 X 1300 X 1675 |